At Plextrusions, we take pride in crafting high-quality custom extruded plastic profiles and tubing, all proudly made in the U.S.A. Choosing American-made products from Plextrusions offers a range of benefits that enhance quality, reliability, and support for the local economy.

At Plextrusions, we take pride in crafting high-quality custom extruded plastic profiles and tubing, all proudly made in the U.S.A. Choosing American-made products from Plextrusions offers a range of benefits that enhance quality, reliability, and support for the local economy.

Uncompromising Quality and Standards

When you buy from Plextrusions, you’re investing in products manufactured to the highest standards, backed by rigorous U.S. regulations and quality control. Our facilities, located in the United States, adhere to strict industry guidelines, ensuring that every extruded plastic profile—whether for medical tubing, automotive seals, or construction frames—meets or exceeds customer expectations. American manufacturing allows us to maintain consistent oversight, utilizing advanced technology and skilled labor to produce durable, precision-engineered solutions. This commitment to quality reduces the risk of defects, offering peace of mind and long-term reliability for your projects.

Faster Lead Times and Local Support

Opting for Plextrusions means enjoying faster lead times and responsive customer service, thanks to our U.S.-based production. Unlike overseas suppliers, our domestic manufacturing eliminates lengthy shipping delays, enabling quicker delivery of custom orders—often within weeks rather than months. Located in the U.S., we provide direct access to our expert team, who collaborate closely with clients to tailor solutions to specific needs, from design to delivery. This proximity ensures efficient communication and support, making Plextrusions a dependable partner for industries requiring timely, high-quality plastic extrusions.

Economic and Environmental Benefits

Purchasing from Plextrusions supports the American economy by creating jobs and fostering local innovation. Our U.S. manufacturing operations employ skilled workers, contributing to community growth and stability, which aligns with the values of businesses seeking to invest in domestic industries. Additionally, producing locally reduces the carbon footprint associated with international shipping, supporting environmentally conscious practices. By choosing Plextrusions, you’re not only getting top-tier extruded plastics but also contributing to a sustainable, homegrown supply chain that minimizes environmental impact.

Trust and Customization

Buying American-made products from Plextrusions builds trust through transparency and customization options unavailable with many overseas competitors. Our U.S.-based production allows for real-time adjustments and personalized designs, ensuring that each extrusion meets your exact specifications—whether for medical devices, automotive components, or construction applications. This flexibility, combined with the assurance of consistent quality and ethical labor practices, strengthens customer confidence. At Plextrusions, we’re proud to uphold the Made in the U.S.A. label, delivering products that reflect American craftsmanship and reliability.

Choosing Plextrusions means opting for quality, speed, economic support, and trust—all rooted in our U.S.-based manufacturing. Contact us today to experience the benefits of our American-made extruded plastics and see how we can elevate your next project.

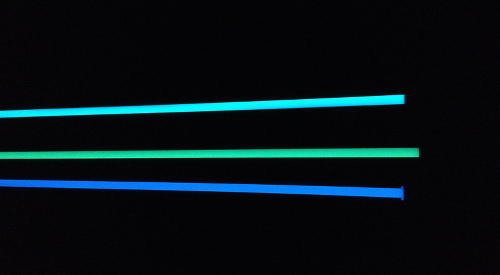

These profile products illuminate and glow in the dark up to 12 hours when charged by UV lighting or incandescent lighting. With our prioprietary processes we are able to extrude luminescent products with a very high percentage of phosphorous pigments that is unheard of in the industry.

These profile products illuminate and glow in the dark up to 12 hours when charged by UV lighting or incandescent lighting. With our prioprietary processes we are able to extrude luminescent products with a very high percentage of phosphorous pigments that is unheard of in the industry. Proud to Offer A Variety of Capabilities and Materials

Proud to Offer A Variety of Capabilities and Materials